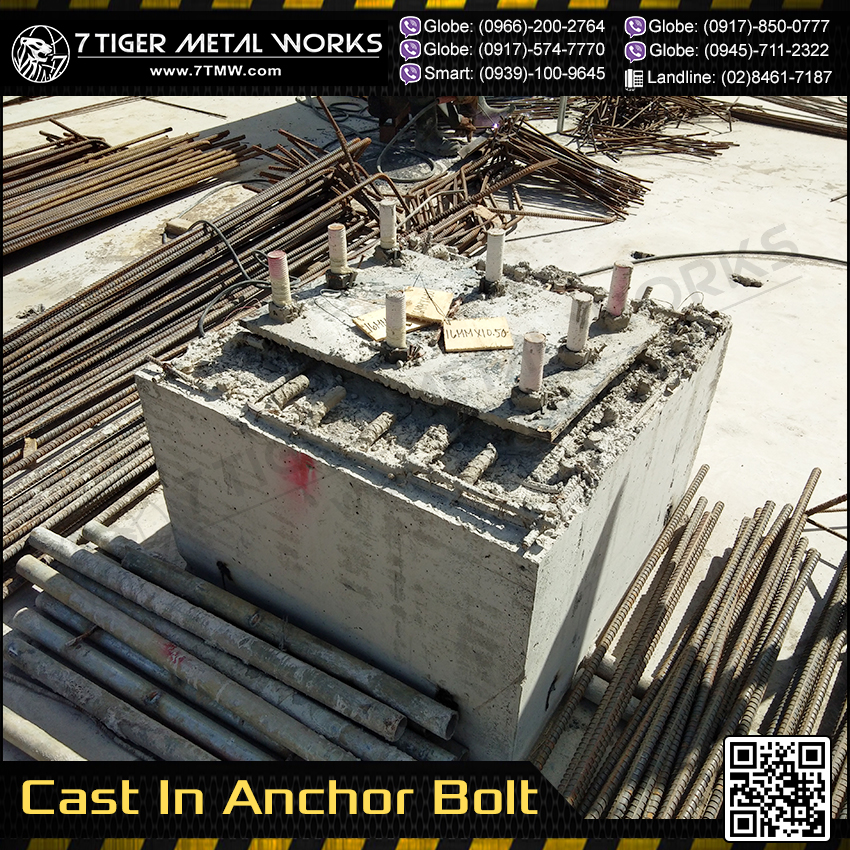

Cast in Place Anchor Bolt

Cast in anchor bolts are a type of fastener that are embedded into concrete during the pouring process. These bolts are designed to provide a secure and long-lasting connection between the concrete and the structure being attached. Cast in anchor bolts are commonly used in construction and industrial applications where a strong and reliable attachment is needed. They come in a variety of sizes and materials, including steel and stainless steel, to suit different project requirements. Whether you’re working on a high-rise building or a bridge, cast in anchor bolts offer a durable and effective solution for your fastening needs. If you’re looking for a reliable and permanent attachment option for your concrete applications, cast in anchor bolts are an excellent choice.

Material Grades for Anchor Bolt

| Material | SCM440 |

|---|---|

| Chemical Composition | Carbon (C): 0.38% – 0.43% Silicon (Si): 0.15% – 0.35% Manganese (Mn): 0.60% – 0.85% Phosphorus (P): 0.030% max Sulfur (S): 0.030% max Chromium (Cr): 0.90% – 1.20% Molybdenum (Mo): 0.15% – 0.30% |

| Mechanical Properties (Tensile Strength) | Ultimate Tensile Strength: 850 MPa (123000 psi) Yield Tensile Strength: 740 MPa (107000 psi) Modulus of Elasticity: 190-210 GPa (27557-30458 ksi) Poisson’s Ratio: 0.27-0.30 |

| Physical Properties | Density: 7.85 g/cm³ (0.284 lb/in³) Thermal Expansion: 11.5 µm/m-K (6.39 µin/in-°F) Thermal Conductivity: 42.7 W/m-K (296 BTU-in/hr-ft²-°F) |

| Hardness | Rockwell Hardness (C Scale): 22 – 28 Brinell Hardness: 201 – 269 HB |

| Heat Treatment | SCM440 can be hardened by heat treatment and is typically quenched and tempered to achieve desired strength and hardness. |

| Applications | Commonly used in applications where high strength and toughness are required, such as in the manufacturing of automotive parts, machine tools, and construction equipment. |

| Material | S45C |

|---|---|

| Chemical Composition | Carbon (C): 0.42% – 0.48% Silicon (Si): 0.15% – 0.35% Manganese (Mn): 0.60% – 0.90% Phosphorus (P): 0.030% max Sulfur (S): 0.035% max |

| Mechanical Properties (Tensile Strength) | Ultimate Tensile Strength: 690 MPa (100000 psi) Yield Tensile Strength: 590 MPa (86000 psi) Modulus of Elasticity: 205 GPa (29700 ksi) Poisson’s Ratio: 0.3 |

| Physical Properties | Density: 7.85 g/cm³ (0.284 lb/in³) Thermal Expansion: 11.7 µm/m-K (6.50 µin/in-°F) Thermal Conductivity: 48.0 W/m-K (333 BTU-in/hr-ft²-°F) |

| Hardness | Rockwell Hardness (C Scale): 20 – 25 Brinell Hardness: 167 – 229 HB |

| Heat Treatment | S45C can be hardened by heat treatment and is typically quenched and tempered to achieve desired strength and hardness. |

| Applications | Commonly used in applications where high strength and toughness are required, such as in the construction of machine parts, gears, axles, spindles, and shafts. |

| Material | ASTM A307 |

|---|---|

| Chemical Composition | Carbon (C): 0.29% max Manganese (Mn): 0.80% – 1.20% Phosphorus (P): 0.040% max Sulfur (S): 0.050% max |

| Mechanical Properties (Tensile Strength) | Ultimate Tensile Strength: 60 (414 MPa) Yield Tensile Strength: 36 ksi (248 MPa) Modulus of Elasticity: 29 x 10^6 psi (200 GPa) Poisson’s Ratio: 0.29 |

| Physical Properties | Density: 7.85 g/cm³ (0.284 lb/in³) Thermal Expansion: 11.7 µm/m-K (6.50 µin/in-°F) Thermal Conductivity: 72.6 W/m-K (502 BTU-in/hr-ft²-°F) |

| Hardness | Rockwell Hardness (B Scale): 60 – 100 |

| Heat Treatment | ASTM A307 can be hardened by heat treatment and is typically quenched and tempered to achieve desired strength and hardness. |

| Applications | Commonly used in structural applications, such as in the manufacturing of bolts, studs, and other fasteners. |

Anchor Bolt Applications

Cast-in-place anchor bolts are commonly used in construction and engineering projects where a strong, secure connection is required between a structural element and a foundation or base. Here are some examples of where cast-in-place anchor bolts may be used:

Bridge construction: Cast-in-place anchor bolts are often used to secure bridge piers and abutments to their foundations, providing stability and strength for the structure.

High-rise building construction: Cast-in-place anchor bolts are commonly used to anchor steel columns and other structural elements to concrete foundations in high-rise buildings.

Industrial machinery: Cast-in-place anchor bolts are used to anchor heavy machinery to concrete floors in factories and other industrial facilities.

Retaining walls: Cast-in-place anchor bolts may be used to secure retaining walls and other structures that require a strong connection to the foundation.

Stadiums and arenas: Cast-in-place anchor bolts are often used to secure structural elements of stadiums and arenas, such as seating, lighting, and scoreboards.

Wind turbine foundations: Cast-in-place anchor bolts are used to anchor the tower of a wind turbine to its concrete foundation, providing stability and support for the structure.

Seismic retrofitting: Cast-in-place anchor bolts may be used as part of seismic retrofitting projects to strengthen existing structures and prevent damage during earthquakes.

Where to buy Customize and fabricated Anchor Bolts

Seven Tiger PH located at

2510 Severino Reyes St, Tondo, Manila City. Philippines

~~Official Numbers~~

Globe (0966)-200-2764

Globe (0917)-850-0777

Globe (0917)-574-7770

Globe (0945)-711-2322

Smart (0939)-100-9645

Landline: (02) 8461-7187