MS plate stands for “Mild Steel Plate”. It is a type of carbon steel plate that contains low levels of carbon. Here are some of the applications of MS plate in construction and anchor bolt:

Construction: MS plates are widely used in the construction industry for various applications such as building frames, beams, columns, and trusses. The plates are used to provide structural support due to their high strength, durability, and resistance to corrosion.

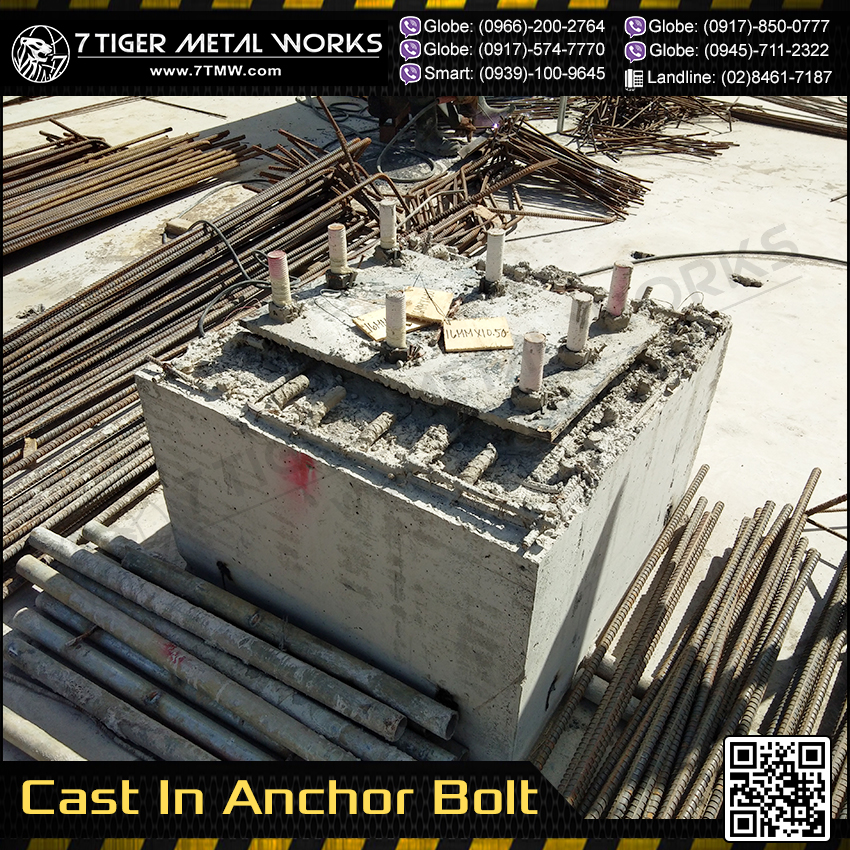

Anchor bolt: MS plates are commonly used in the manufacturing of anchor bolts, which are used to secure heavy machinery and equipment to concrete surfaces. The plates are welded onto the end of the anchor bolt to provide a larger surface area for distributing the load and reducing the stress on the concrete.

Base plate: MS plates are used as base plates for structural steel columns and other components in buildings and bridges. The plates provide a stable and secure footing for the steel components and help distribute the load evenly to the foundation.

Floor plates: MS plates are used as floor plates in industrial and commercial buildings, such as factories and warehouses. The plates provide a non-slip surface for workers and heavy equipment, and are often used in areas where the floor is subject to heavy traffic or machinery.

Grating: MS plates are used to manufacture steel grating, which is used as a flooring material in industrial and commercial buildings. The grating provides a durable and slip-resistant surface for workers and equipment.

Formwork: MS plates are used as formwork in the construction of concrete structures such as walls, columns, and beams. The plates are used to create the desired shape and size of the structure and provide support during the pouring and curing process.

Stair treads: MS plates are used as stair treads in buildings and structures. The plates provide a durable and slip-resistant surface for people to walk on.

Technical Specification for MS plate

| Property | Value |

|---|---|

| Material Type | Mild Steel Plate |

| Thickness | 1mm to 100mm |

| Width | 1000mm to 2500mm |

| Length | 2000mm to 12000mm |

| Tensile Strength | 410MPa to 540MPa |

| Yield Strength | 250MPa to 350MPa |

| Elongation | 20% to 36% |

| Hardness | 120HB to 250HB |

| Density | 7.85g/cm3 |

| Thermal Conductivity | 52.4 W/mK at 0-100°C |

| Melting Point | 1420°C |

| Modulus of Elasticity | 210 GPa (Young’s Modulus) |

| Poisson’s Ratio | 0.27 |

| Coefficient of Thermal Expansion | 11.7 × 10-6/°C (at 20-100°C) |